|

|

|

custom thermoformed heat compression EVA foam cases molds design, cost, price |

| Author : Tony Date : 4/23/2021 8:39:07 AM |

Thermoformed mold is also been called as the EVA case mold, heat compression mold, etc. most of the EVA case factories will ask for the mold cost if you want to make an EVA case.

1. Does every EVA case need a mold?

Every EVA Case needs a thermoformed mold to yield the shape, so we need to set up a mold based on devices shapes and dimensions.

2. Why should we pay for the mold cost?

Yes, Clients need to pay the mold cost if they want to set up a new case mold.

3. Can I use an available mold?

Sometimes the clients do not want to pay for the mold cost and just need a similar sized EVA case; in fact it’s not easy to find a similar size mold since we already have more than 10 000 molds in stock.

But most of the EVA case molds are already have client’s logos on them, so we could not share them although the sizes are very similar. Eva case with embossed logo

4. What’s the mold cost?

Mold cost is including the mold material cost, design and mock up cost, CNC machine engraving cost, etc.

5. Shall we send our devices to EVA case factory to set up the mold?

Yes, the best choice is sending the devices or samples to factory to set up the mold. You also could provide 3d or 2d format files to save the freight cost.

6. Shall we provide the 3d format file to EVA case factory to set up the mold?

Yes, but PDF file or CAD file is ok; we could draw 3d format file based on the PDF or CAD file.

7. Is EVA case mold expensive?

For small size EVA case, the case mold cost is no more than 200 USD, so it’s not expensive at all.

But for the large size EVA case, or other large sized heat compression molded parts, the mold cost is very expensive, generally speaking, the Heat compression mold is cheap than plastic injection mold.

8. Is EVA case mold cost refundable?

EVA case factory will afford for the mold cost if clients could reach the order quantity, but client need to pay mold cost first, and the mold cost will be refund or from the production payment.

9. Does the EVA case mold belong to me if I pay for it?

Yes, of course, as the Trustworthy EVA case factory, we won’t use the mold for other clients, we will follow the rules, and we also could sign in the Confidentiality agreement, so no need to worry about it.

10. Can I have my own design/shape/pattern?

Yes, you could design your own case with custom shaped and pattern, we will check it’s feasibility, just like that you could not print the some colors on the paper even you could see them on the computer screen.

11. Is there any limitation for the Mold?

Most of the factory told you that they could make EVA case with any shape, any design, any size, etc. that’s bullshit, you must know that every technology has its limitation, so the EVA case factory need to consider the tech, material, fabric, and other factors. So we need to make the feasibility analysis before the mold explore. Such as the ratio of length to height, the malleability of the EVA foam and the radius of the round corner, etc.

In a word, there could not be any undercuts in EVA case heat compression mold, and the corner could not be right angle!

12. What’s the lead time to set up the mold?

If clients could provide 3d format file or the devices, we only need 2 days to set up the mold. But for the large sized mold or the complex mold, it costs more time to be engraved by CNC machine.

13. Is there any guarantee if I am not satisfied with the thermoformed mold?

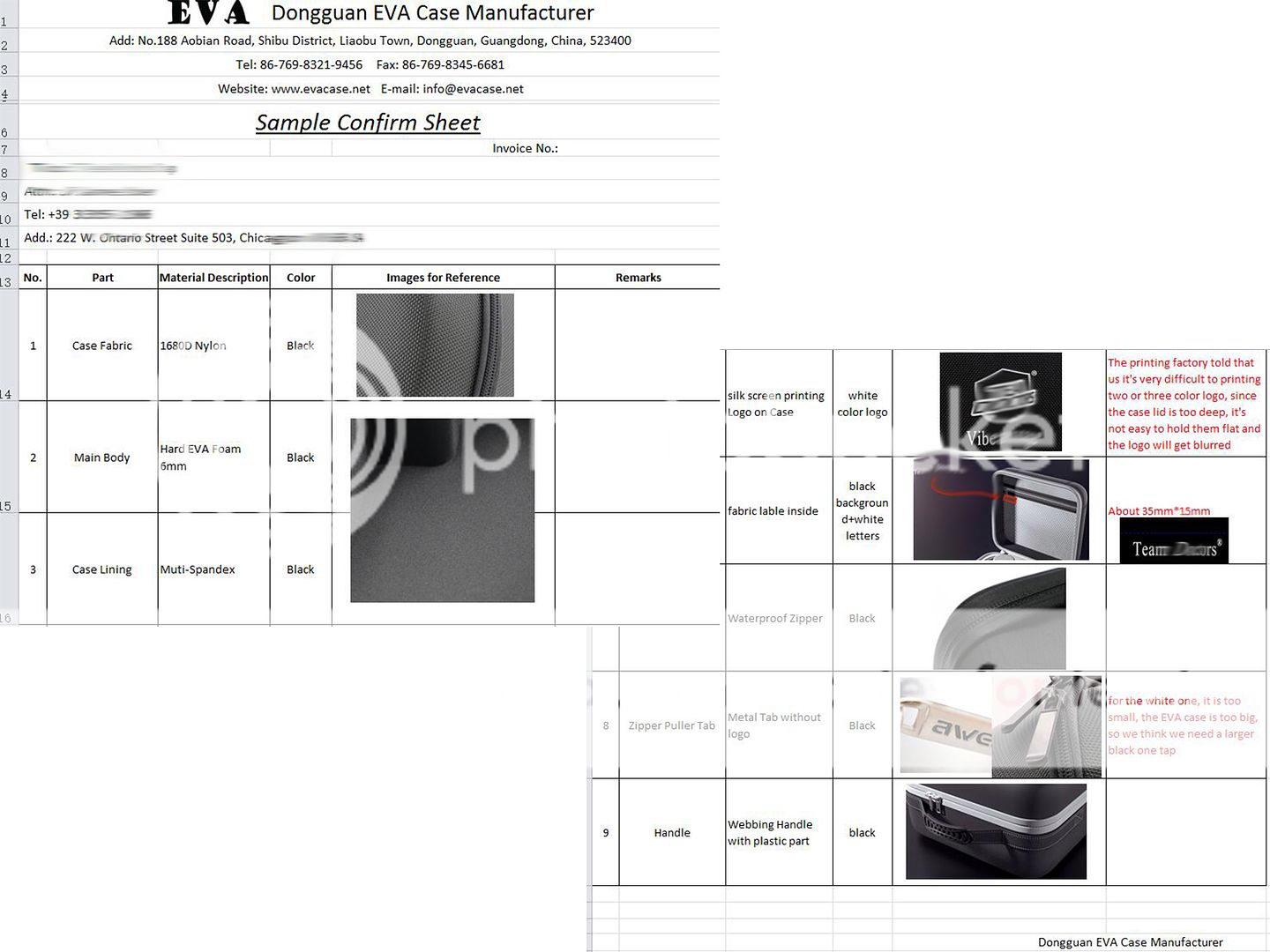

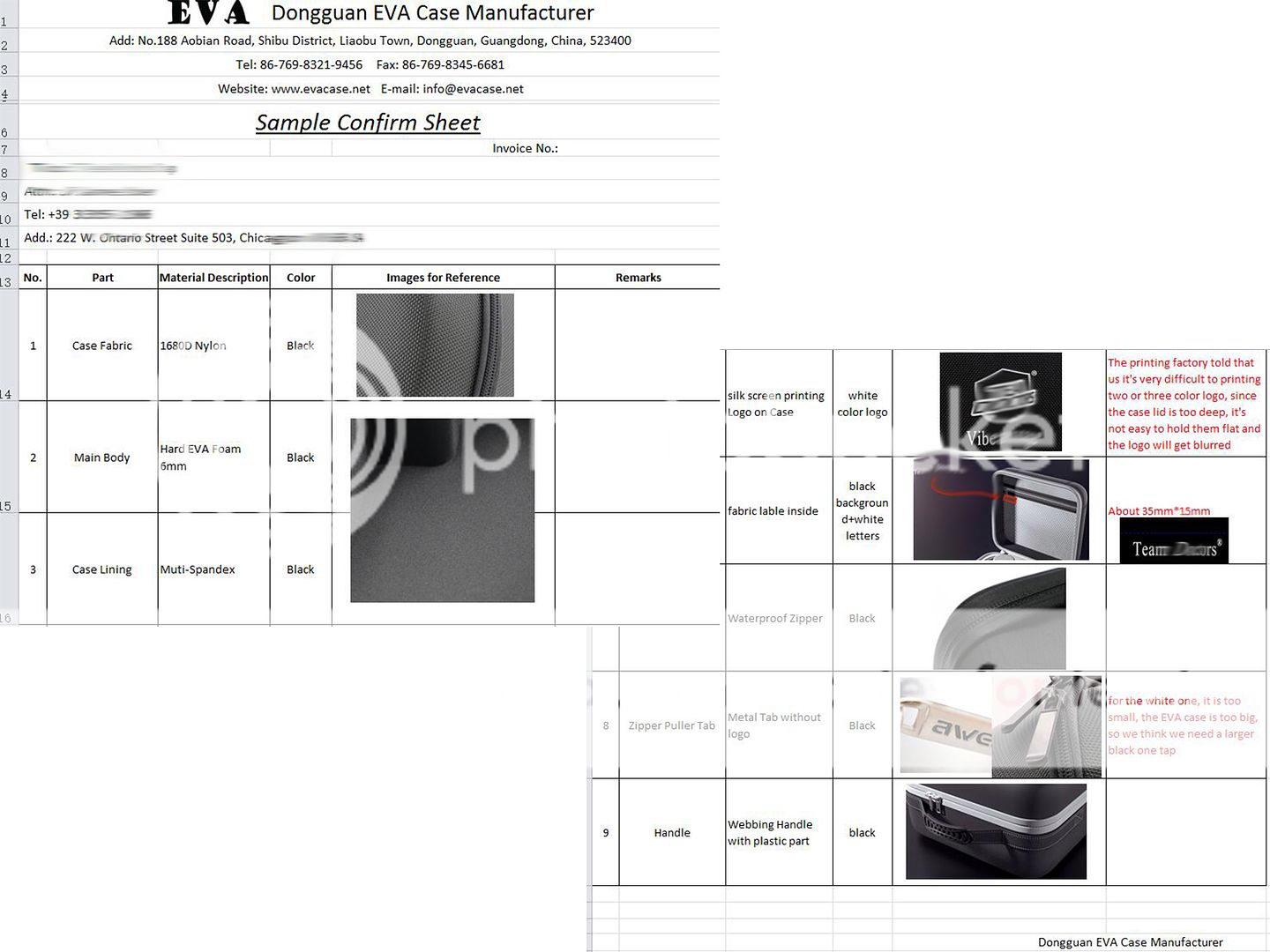

The EVA case factory will take responsibility for the mold, we must set up the mold based on client’s requests, so we will send the sample confirm sheet to clients to make details clear. We will refine the mold or set up a new mold if we made mistake during the mold setting up, and do not ask for any charges.

But clients will afford the cost if they provide the wrong devices or wrong data.

14. Will the EVA case factory use my mold to produce EVA cases for other clients?

No need to worry about it!

Dongguan EVA Case Manufacturer won’t use your mold to make sample or production for other clients!

15. Can I have my logo on the EVA case mold?

Yes, we strongly recommend clients to add their company logo on the molds, it’s totally free! Other client could not use the mold any more!

16. How can we start to make an EVA Case mold?

Send us the devices/samples/files/designs to us, we will check and send the suggestions to you, once you agree with the suggestion, we will send you the sample confirm sheet, clients check the sheet with no comments, they pay the mold cost, Dongguan EVA Case Manufacturer will set up the mold based on the sample confirm sheet.

17. What kinds of files are required to set up the EVA case mold?

3d format files, such as the igs, step file.

2d format file, such as the CAD file, PDF file, AI file, etc.

18. What the best material to make the EVA Case mold?

Mold material: copper, stainless steel, aluminum, iron, wood, plaster, etc.

High purity aluminum, common aluminum, and the recycled aluminum,

The most popular material is the aluminum, the common and high purifies aluminum,

19. Is the logo replaceable on the EVA case mold?

In the past years, some factory replaced the logo to save cost, but there will be a small around the logo, most of the clients do not like it. So they prefer to set up a new mold with their own logo.

Another one is, the case lid surface is flat, and the mold is blank without any logo, we add a heat stamped logo after the case finished.

20. How many times could be used for the EVA case mold?

Dongguan EVA Case Manufacturer could guarantee the mold could be used for More than 200 000 times!

21. Are the thermoformed molds same to make sample and for production?

Yes, they are the same one, but for large amount production, the factory needs to set up more molds to save time, sometimes we need to set up more than 10 sets of molds with same parameter.

For more questions, you could write an e-mail to our professional sales manager: richard@evacase.net, we will feedback to you ASAP.

|

|

EVA Laptop Cases/ HDD Cases/ Camera Cases

EVA Laptop Cases/ HDD Cases/ Camera Cases